Walking new paths to make things better

Our aim: solutions that make the demanding work with diving robots as easy and efficient as possible

We are a team of high-experienced engineers for ocean technology with a deep connection to the sea. Our aim is to radically simplify the survey and discovery of our oceans, because the more we understand the marine environment, the better we can protect it. And this idea of leaving the beaten path and finding new and better ways to ensure a sustainable use of marine resources is what strongly drives us every day.

Experienced explorers: The Crew

Nico Günzel

Managing director, founding team, M.Sc.

specialized in mechanical load analyses (fem), pressure-tolerant electronic components and optoelectronics

Robert Balduhn

Technical director, founding team, M.Sc.

specialized in fluid dynamics (cfd) propulsion and 3D printing

Maximilian Hackl

Engineer, founding team, M.Sc.

specialized in network-components, pressure-tolerant microelectronics and power electronics

MICHAEL LAMPERT

Data software developer, M.Sc.

specialized in automation, data-management and robot operating system (ROS 2)

GEORG DEGNER

Robot mechanic & workshop, metalworker

responsible for post-processing and assembly of robot components, robot maintenance, operation and maintenance of our 3D printer and inventory management, ROV pilot

JULIANE ZIEBUHR

People & culture, B.A.

responsible for internal organization, management assistance, social media, networking and human resource management

Christopher Rieß

Business development & sales, M.Sc.

responsible for sales, strategy and customer relationship management

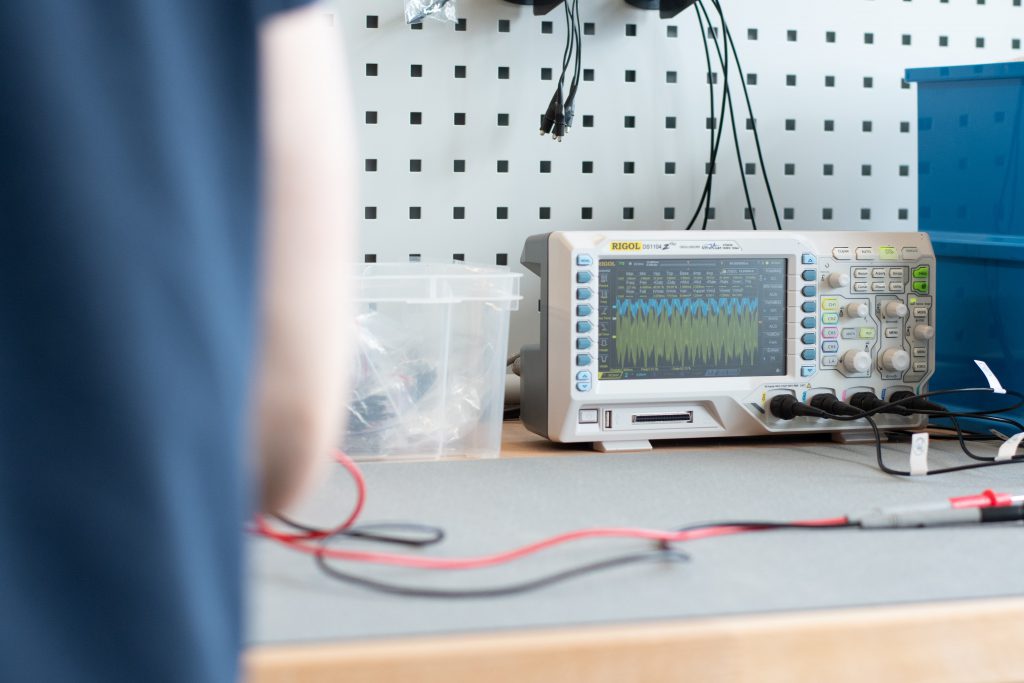

Mathias Schulz

Electrical engineer, M.Sc.

specialized in electrical engineering, PCB design, hardware development, prototyping, R&D

Johannes Simon

Software developer, M.Sc.

responsible for back-end software development and programming

Sameur Hedhili

Software developer, Engineer

responsible building marine software systems based on ROS 2

Karoline Gerth

Engineer, M.Sc.

responsible for mechanical construction

We’re always looking for pioneers:

become a part of our team!

Made for the sea

by people who know it

We are located in Rostock, right by the water, in the heart of the new Ocean Technology Campus (OTC). Our site offers everything we need to feel at home and work successfully: bright offices with modern workstations, a varied canteen and a state-of-the-art workshop, but also an abundance of innovative spirit and stimuli thanks to contact with other great companies on the campus.

Let’s go for a walk:

our 360° lab & office tour